Industry Solutions Laser Marking of Electronics & Semiconductors

Printed circuit board

Circuit boards and electronic components are marked with permanent, solder-resistant and machine-readable laser markings, in order to guarantee accurate identification and traceability, which in turn guarantees a flawless quality assurance process across the entire life cycle chain and the process.

Typical marking contents range from complex 2D-data matrix codes to alphanumeric characters and customized contents.

Housing

Most of the housings that are used for electrical or electronic components must, due to reasons that relate to traceability, quality assurance and trademark protection, be marked: with simple alphanumeric codes, complex 2D codes, logos or customized data. Laser marking is a cost-efficient and secure marking process that satisfies these requirements. The quality of the markings is high, the imprinted characters are easy to trace and most of the materials that are used to build housings can be marked with the laser.

Electricity meter housing with individualized barcode

The black coating layer that is applied to the lower part of an electricity meter’s aluminum housing is removed, and the marking becomes visible as an individual barcode. The barcode that is applied with the help of a laser is machine-readable and can be read by a scanner.

SMD component

SMD components are getting smaller and smaller, along with the markings that they carry, which must be applied with a high degree of precision. Since most components are microscopically small, the data contained in the marking seldom exceeds the micrometer range. An example of a possible SMD marking: 0.6 mm x 0.8 mm. FOBA’s marking lasers mark SMD components made of various materials: ceramic, various synthetic materials (e.g. epoxy resins), metals and metalloids (silicones). The possible contents of markings range from manufacturing and tracing codes to simple alphanumeric characters and complex 2D codes, logos and customized data. The image to the right shows a relatively large microchip with a perfectly readable identification on its 4 mm x 4 mm marking surface. The marking time was 45 ms.

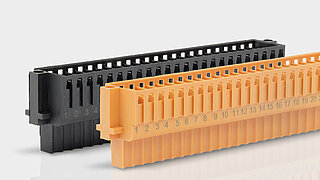

Component strips

The assembly and the laser marking of the epoxy-coated chip are carried out vis-a-vis the carrier strips and are thus part of the process chain. There is no need to separate the individual chips from the process, which would have entailed a large degree of expenditure. Rather, they are processed in the process itself.