Vision Systems MOSAIC – Laser Marking without Fixtures

For fixture-free processing: MOSAIC

Overview

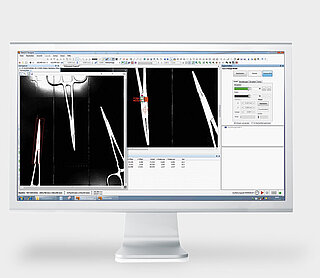

The US-patented MOSAIC feature addresses the key challenges of accurately aligning marks on large parts regardless of the part position and orientation. MOSAIC uses the internal camera of the laser to create an image of the marking field by simulating a straight down camera view. The straight down view eliminates the side view distortion typically created when using an external camera, and enables the system to accurately mark parts regardless of their placement.

Benefits

- Fixtureless operation

- Easier and faster marking process

- Limited operator training

- High ROI

- Significant cost saving

- Suitability for both manual and automated operations

Videos

FOBA Mosaic – Fixture-free laser marking

The US patented feature addresses key challenges in precisely aligning marking contents to large components – regardless of their position in the marking laser system.

Fixture-free marking of artery clamps

M3000-P with 30W fiber laser marking system and MOSAIC

Fixture-free marking of brake disc

M3000-P with 30W fiber laser marker and MOSAIC

Fixture-free etching of bearings

M2000-P with 20W fiber laser etcher and MOSAIC

Fixture-free bearing marking with roller inspection

Vision assisted laser marking of bearings and detection of missing and inverted rollers: M2000-P with 20W fiber laser marker and MOSAIC as well as AOP (Advanced Operator Interface)

Get the most out of your first FOBA purchase!

Over 5,000 installations confirm this: FOBA laser marking devices lead quickly, precisely and economically to high-quality product and material marking of stationary or moving components. Join the group of satisfied FOBA customers and get a free first class upgrade!

Different options are possible in a personal consultation with one of our laser marking experts. After getting an overview of your marking requirements, our experts will provide you with a customized upgrade for your project.

Machine Upgrade: You have large parts or product trays, but not a large budget for a big machine? Choose our M2000 Laser Marking Station and get an upgrade to the bigger version, the M3000.

Vision Upgrade: Why just check the mark alignment in your product tray using our IMP camera system, when you can omit the tray completely using FOBA MOSAIC.

Individual Upgrade: Get an upgrade that is tailored to the needs of your project.

Download

| File Name | File Size | File Type |

|---|---|---|

|

Software, Vision, Workflow - Overview (EN)

.pdf,

2,26 MB

|

2,26 MB | |

|

MOSAIC Infographic

.pdf,

181 KB

|

181 KB |