Software for Laser Marking

FOBA AOP NT

Advanced Operator PlugIn NT

For simple, safe and efficient operation: A graphical operator interface with optimal functionality for maximum process reliability

Overview

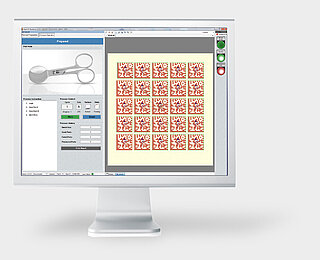

FOBA's Advanced Operator PlugIn NT (AOP NT) is a focused graphical user interface for FOBA laser marking equipment. The PlugIn is directly integrated in FOBA's MarkUS marking software, and has been designed for improving production efficiency, reducing costs and increasing throughputs during the laser marking process in the medical technology field as well as various other industries.

In the AOP NT, the essential steps of the marking process are clearly visualized in order to ensure a quick, intuitive, secure and almost error-free operation of the FOBA laser system. The simplified graphical user interface ensures for the fast, safe and reliable laser marking of all sorts of products, parts and devices. Protected from incorrect entries, a barcode scanner is used to transfer all job related data into the laser marking system. The marking process is fully visualized, including a part preview, clear operator instructions, marking process status information and direct feedback of code validation and mark verification results. Thus, the AOP NT helps to accelerate production processes and to reduce scrap during part marking which can add up to savings in the range of 40,000 Euro per year (given a 3 shift operation with 5 job changes per shift).

Video

FOBA AOP NT / Medical PlugIn

Easier, safer and more efficient marking.

Benefits

Stable marking process

The visualized process, reduced to the essentials, minimizes operator tasks and reduces operating errors.Video, picture instructions and an intuitive GUI make the process easy to execute.

Increased production efficiency and throughput

The focused marking process ensures greater production efficiency, reliability and throughput. The reject rate is reduced

Process standardization and database connectivity

Data integration by means of database connection MS Access (SAP, Oracle on request), History, reporting, logging.

Main fields of application

Optimization of production efficiency

Cost reduction through scrap reduction in laser marking

Increase throughput by accelerating laser marking

Technical specifications

FOBA Advanced Operator PlugIn NT

| Features | |

| Complete process control (either in German or English) | |

| Data integration via database connectivity MS Access (SAP, Oracle and others on request) | |

| Customer-specific user instructions | |

| Status information, process visualization | |

| History, reporting and logging | |

| Individual: configuration and variable setting (up to 6 sides) | |

| User login and program approval with 2nd level authorization process | |

| First-part-inspection and approval process | |

| Batch processing | |

| Single- and multi-side marking (up to 6 sides) | |

Supports FOBA power monitor (laser power measurement) | |

| Pack and Go Job-security support | |

| Multisided multistep mode | |

| Free programmable homing and loading position of the axis | |

| Enhanced fixture support | |

| Recipe loading to load all job data based on GS1 code AI (Application Identifier) at once | |

| Video instructions. In addition to illustrated instructions, instruction videos are now available. These provide more security for inexperienced users. | |

| Rework mode to ensures that only incorrect inserted parts need to be realign | |

| Enhanced report and process logging capabilities | |

| Laser calibration monitor and calibration reminder | |

| Improved variable support allows users to change the variable value more easily | |

| Improved extended first part inspection to reduce cycle times | |

| Improved parts arrangement and result view | |

| System requirements | |

| Available for M1000, M2000, M3000 | |

| Laser systems on request | |

| MarkUS 2.12.40.0 or higher | |

| MarkUS Plugins 2.12.0 or higher | |

Download

| File Name | File Size | File Type |

|---|---|---|

|

Product datasheet AOP (Advanced Operator Plugin)

.pdf,

527 KB

|

527 KB | |

|

Product Overview

.pdf,

6,19 MB

|

6,19 MB |