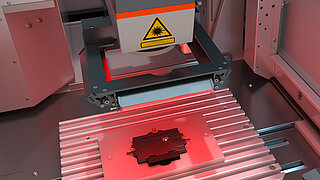

Plastics Laser Engraving, Etching and Marking of plastics

White paper "Plastic laser marking"

Based on the properties of a plastic, its functional purpose and its intended use the requirements for marking it are varying. A great diversity of plastics are being deployed especially in the automotive or medical industry. The quality of the marking on a plastic part is determined by the type of the selected laser etching system, the utilized marking parameters, but also by the use of special additives in the plastic mix.

Our white paper offers a broad overview of the industrial use and the laser marking of plastics and resins

Key button and rocker switches: Technical controls in day-night design

The day/night design marking allows for a perfect visibility of symbols and signs on backlit operational controls in any lighting conditions.

Sharp black and white contrasts in the daylight and striking light-dark contrasts at night can be created through precise removal of separate coating layers on transparent or translucent base material.

Laser ablation or paint removal is a flexible and efficient method for high-end day and night applications which can be found in automobile and aircraft industries as well as in the production of electronics and household appliances.

Cannula

Hygienic laser engraving and marking of plastics for medical technology with the help of UV laser markers. The product surface is colored photochemically. The marking process produces such little heat, that sensitive products and delicate materials remain largely unharmed. The surface of materials marked in such a manner remains smooth, making it impossible for germs to take root.

With a typical pulse duration of 20 ns and a radiation diameter of 10 µm, the UV marking laser colors the surface without damaging it. This process can be used to mark medical products such as cannulas or insulin pumps and it ensures that the labels are long-lasting and sterilizable .

Height of the marking data: 1.5 mm

Marking time: 11.4 s

Lamp holder from plastic

Color change in an injection molded part made of light plastic is brought about by means of carbonizing.

This application is typically used for permanent and durable marking of housings of all types, relays, switches, plugs and other electronic components.

Animal ear tags

Typical color change marking on an animal ear tag made of rubber compounds, as is used for marking and identification in livestock farms.

Automobile component made of plastic that was specially manufactured for laser marking

Color change on a plastic that was specially manufactured for laser marking. Laser marking bleaches the dark plastic and the marking becomes visible.

SMD component

Micromarking on an epoxy resin casing. Typical electronic application for SMD components and other components by means of engraving and generation of color change.

PEEK medical devices

PEEK (Polyetheretherketon) is especially appropriate for most medical applications because it is highly temperature resistant and thus can be repeatedly sterilized, furthermore it is biocompatible and transparent for x-ray examination. PEEK is frequently being used for implants, mesh implants or dental implants.

The best marking results can be achieved with pulsed Ytterbium fiber lasers of the FOBA Y-Series.

The PEEK implant shown aside serves as an interbody spacer for spinal fusion surgery. It has been laser marked with a tiny code to ensure safe traceability throughout its whole product life cycle.