Overview

You have the task of integrating a laser into a special machine with X, Y and Z axes and possibly even a rotary (swivel) unit? Or do you want to integrate a laser into an automated production line, equipped with motorized Z-axis for adjusting different working distances for several products? Would you also prefer controlling all the parameters relevant to marking from one program?

FOBA Middleware software solution package has been developed for the easy integration of FOBA's basic laser marking systems into your production environment. It facilitates installation and setup, and also ensures a continuously reliable and user-friendly marking process.

Benefits

Integration simple and cost-effective

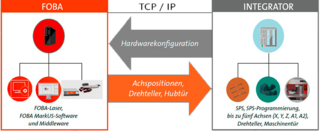

Comprehensive control via one software, only TCP/IP connection is required for the PLC

Integration future-proof and flexible

Machine hardware (PLC, axes, motors, rotary/swivel unit, machine door, rotary table) according to your own choice, only PLC program for communication with FOBA system required

How does FOBA middleware ease particular challenges when integrating a marking laser?

Certain marking applications require the integration of a large number of hardware and software components. This applies, for example, when a laser is installed in a special machine with X, Y and Z axes and possibly even a rotary or swivel unit. Or when the laser is integrated into an automated production line with a motorized Z-axis with variable working distance for different products.

To make these challenges easier for our customers, we have developed FOBA Middleware, a solution that enables all parameters to be controlled in a single program. The user can then set up a marking job from the familiar graphical user interface of MarkUS without further programming in the FOBA marking software.

So you have one solution for everything: With the FOBA integration package, you can combine all marking-relevant parameters in one laser job. This includes marking content, laser parameters, axis positions and also the optional camera control for a FOBA laser with integrated camera.

Product marking in perfection!

We offer the simplest and most complete solution for laser marking processes on the market, combining advanced laser technology with a state-of-the-art vision system. The system checks the correct parts and prevents the marking of incorrect parts.

What additional benefits does this software solution offer?

The simplified application and setup allows each party to focus on their strengths and weaknesses: The integrator manages the entire mechanical engineering from a mechanical, electrical and control point of view, while FOBA as the laser partner contributes the laser technology, including the systems and software.

As all factors relevant to marking are combined in one laser job, control and integration are not only simpler but also more cost-effective. There is no longer any need for two "recipes", one for the axis movements in the PLC and the other for the content control on the laser PC.

You can use the machine hardware of your choice, such as the PLC, axes and motors, rotary/swivel unit, machine door or turntable. All your PLC needs is a TCP/IP connection and a PLC program created by you for communication with the FOBA middleware.

Download

| File Name | File Size | File Type |

|---|---|---|

|

FOBA Middleware flyer

.pdf,

508 KB

|

508 KB | |

|

Software and Vision Overview

.pdf,

2,26 MB

|

2,26 MB |