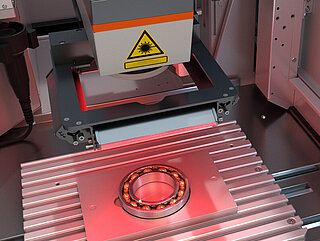

Welcome Direct Part Marking with Laser

Ultra black marking

Learn more about the challenges of marking medical stainless steel and how to overcome them with an ultrashort pulse laser.

Compact, versatile, easy to integrate: FOBA TITUS™

Laser marking systems can be so simple!

Find out now what makes our little one so big.

Experts in Industrial Laser Marking

For five decades, we have been writing with light, developing and manufacturing leading laser marking solutions for direct part and product marking. With our internationally proven laser and application know-how and industry-tested marking lasers and laser marking workstations, we reliably and economically make our mark on countless products in all industries. Integrated imaging, innovative software functions and comprehensive services as well as globally competent consulting and first-class customer service nicely complete our portfolio.

Brand new: Ultrashort Pulse Laser

"ULTRA" in every way: F.0100-ir is built ULTRA COMPACT, marks ULTRA BLACK and is ULTRA FAST. With the continuously adjustable pulse width between femto- and picosecond range, the marking laser offers a wide range of applications, maximum marking precision and outstanding process stability.

Applications

We love to solve the most demanding applications! Be it in the medical device marking or automotive part marking sectors or in any other industrial product identification and traceability field.

Industrial Solutions

We help medical, automotive, electronics, and plastics and metalworking companies to make permanent UDI/UID, identification, decoration and branding marks to ensure reliable traceability. Top quality and seamless line, machine or process integration and automation are always part of the solution.

Service & Support

Our service begins long before the laser purchase, and it's about maximum uptime and customer satisfaction. Therefore our services ranges from product and application consulting, installation and training to technical and parts service at global locations.

Latest News & Insights

FOBA Laser Marking + Engraving, international experts in industrial laser marking, have partnered with the Technological…

FOBA Laser Marking + Engraving is part of the DMG MORI process chain with a marking workstation of the FOBA M-Series,…

Black marking is a term used in the field of laser marking. The term refers to an effect that creates a deep black,…

This question inevitably concerns all those looking for a coding solution. That's why we asked our laser experts what is…

Following Brexit, products that currently bear a CE mark require a new UKCA (UK Conformity Assessed) mark to remain or…

FOBA Laser Marking + Engraving, international experts in industrial laser marking, have partnered with the Technological…

FOBA Laser Marking + Engraving is part of the DMG MORI process chain with a marking workstation of the FOBA M-Series,…

US-Product premiere at the trade show: FOBA Laser Marking + Engraving presents its ultrashort pulse laser for…

With the UDI system (Unique Device Identification) manufacturers are obliged to identify and register medical devices.…

We bring you up to date on the current status of UDI direct marking of medical devices and give an overview of the UDI…

Learn how LPKF, as a supplier of laser-based production solutions, integrated FOBA's Titus™ marking head into a laser…

About us

Highest technological laser and application know-how. Innovative customer-specific solutions. Worldwide competent consulting and first-class customer service. This is what sets FOBA apart. That is: Laser at your service.