Dental Implants Marking – UDI Codes Put Under the Microscope

Laser light is highly focused and fast so that the surrounding material is only slightly affected during the marking process. Laser is thus able to create even the smallest marks with high contrast and sharp boundaries.

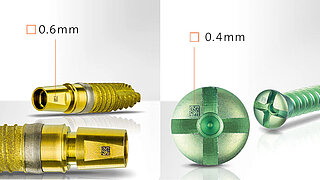

Pictured below are tiny jawbone screws, colored green and pink, as well as blue and yellow dental implants, marked with UDI codes that are smaller than half of a mm².

Laser marking on dental implants is challenging not only because of the limited space, but also because of the cylindrical and respectively the conical surface form. Dental implant manufacturers use direct part marking in order to benefit from product traceability and protection against incorrect manufacturer specifications or counterfeiting, e.g. in case of product recall or patient complaints.