Laser Marking on Titanium – High-quality Marks on Valuable Material

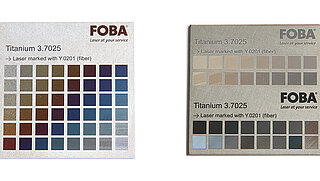

Expensive materials like titanium, and especially the products made from it, require markings of an appropriate high quality. In order to demonstrate the marking capabilities of a pulsed fiber laser on titanium, we have marked the material with 80 fields of different colors on plates of 5 x 5 cm (1.97 in²) for our sample case. By specifically adapting the laser parameters, it is possible to obtain multiple shades and intensities of colors.

Beside the sharpness of the outline, it is also the color contrasts that contribute to marking quality. Dark marks and codes guarantee the best possible legibility and longest durability, which is why black marking is utilized most often. Additionally, the marking of logos or decorative elements sometimes requires colored laser marks.

While engraving causes surface erosion and thus creates texture on the material, annealing marking affects deeper layers of the material, which can also cause color effects. During marking tests, FOBA’s application engineers identified the appropriate laser parameters to create the desired color on the applied material. In this case, we used type 3.7025 titanium. It is not only the parameters like wave length, laser power or pulse frequency that vary, but also the marking time that differs. The annealing marking of the dark fields took more than twice as long as creating the colored fields.